Gas Pipeline Project

1.Well site device

Well site device is provided with the following three functions:

1. Control the yield of gas well;

2. Control the delivery pressure of natural gas;

3. Prevent the generation of hydrate in natural gas.

Equipment includes heating furnace, pressure regulating, separating, and measuring equipment.

2.Gas gathering station

Gas gathering station at room temperature: natural gas heating furnace, three-phase separation.

Gas gathering station at low temperature: low temperature separator, flash separator, high pressure separator, gas-gas heat exchanger, heater, gas-liquid heat exchanger.

3.Gas gathering line

Natural gas is produced in gas field, processed in united station and then transmitted outward.

1、United station: 1. Gas gathering station unit: main function is oil-gas two-phase separation, including such equipment as pig receiver and launcher, corrosion monitoring head, oil-gas separator.

2�����、Dehydration and dehydrocarbon unit: main function includes natural gas dehydration and condensate oil removal; main equipment includes adsorption column, stripper, heat exchanger, air cooler.

3�����、Booster station unit: an alternative of dehydration and dehydrocarbon unit, used to increase gas pressure; main equipment includes air compressor, air cooler.

4�、Desulfurization unit (only for sulfur-containing natural gas): main equipment includes acid gas absorption column, waste heat reactor, process gas furnace, Klaus reactor, cps reactor, hot forging furnace, liquid flow trap, tail gas treating column.

5、Condensate oil unit: process the condensate oil separated from natural gas. Heat exchanger, distillation column, condenser, return tank and finished product tank.

6����、Some other auxiliary units, mainly including conduction oil system, propane refrigerating system, start-up boiler room, air compressor room, condensate oil spherical tank, flare tower, pipe support unit, air & nitrogen station, fire fighting system, power distribution station system, main centralized control building, dormitory camp, spare materials warehouse.

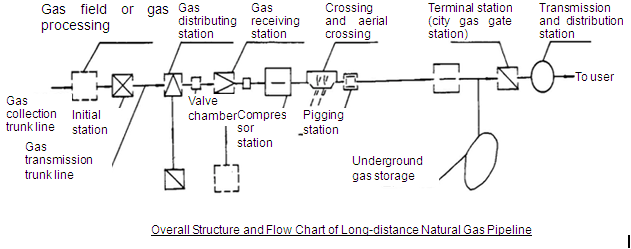

4.Gas transmission station

Distributing station: filter separator, metering skid, pressure regulating skid, vent riser, blowdown drum.

Pigging station: cyclone separator, receiver and launcher, vent riser, blowdown drum.

Distributing pigging station: filter separator, cyclone separator, receiver and launcher, metering skid, pressure regulating skid, vent riser, blowdown drum.

Initial station: receiver and launcher, filter separator, metering skid, pressure regulating skid, vent riser, blowdown drum.

Terminal station: filter separator, metering skid, pressure regulating skid, receiver and launcher, vent riser, blowdown drum.

Intermediate compressor station: receiver and launcher, filter separator, metering skid, pressure regulating skid, vent riser, blowdown drum.

Natural Gas Processing

Gas gathering device, desulphurization and decarbonization device, dehydration device, dehydrocarbon device, acid gas processing device, condensate oil stabilizing device, amine purification device, valve bank area of external transmission station for purified gas, external transmission station for condensate oil, flare and venting system, condensate oil tank farm.

Main acid gas in the natural gas includes CO2 and H2S; for gas transmission via pipeline, H2S<20mg/m3, and for raw material of methanol synthesis, H2S<1mg/m3. The process where H2S and organic sulfide are separated from acid natural gas is called desulfurization; CO2 removal is called decarburization.

The main purpose of desulfurization is to prevent the generation of sulfur dioxide and other air-polluted gases from burning natural gas; the purpose of dehydration is to prevent the formation of crystalline hydrate in the natural gas during the transmission via pipeline under high pressure to block the pipeline; main purpose of dehydrocarbon and condensate oil is, on one hand, to separate two and more carbon atom compounds from natural gas (e.g. LPG, butane (a component of lighter)) for other more useful purposes; on the other hand, prevent the formation of droplet during the low temperature transmission of natural gas to affect transmission efficiency.

1.Desulfurization and decarburization device

Amine absorption column, rich solution flash column, amine regenerating column, MDEA barren/rich solution heat exchanger, barren solution cooler, regenerating column reboiler, acid gas condenser and cooler, acid gas aftercooler, condensation water cooler, gravity separator of feed gas, wet purified gas separator, rich solution flash tank, reboiler condensation water tank,

2.Dehydration unit

Wet purified gas coalescer, coalescer condensate storage tank molecular sieve dehydrating tower, product gas dust filter, resurgent gas/cold air heat exchanger, resurgent gas heating furnace, resurgent gas cooler, resurgent gas separator, resurgent gas separator, resurgent gas compressor.

3.De-hydrocarbon unit

Dry gas pre-cooler, product gas air cooler, wet purified gas separator, dry gas separator, low temperature separator, dry gas coalescer storage tank, purified gas storage tank, dry gas coalescer, compressor unit;

4.Acid gas processing unit

Acid gas separator, acid water pressurizing tank, liquid sulfur catcher, blow down tank, main burner, main combustion furnace, tail gas incinerator burner, tail gas incinerator, acid gas preheater, air pre-heater, heat recovery boiler, primary sulfur condenser cooler, secondary sulfur condenser cooler, heat exchanger, reactor, tail gas flue, tail gas chimney.

5.Condensate stabilizer

Condensate stabilizer tower, acid water stripping tower, stable condensate cooler, condensate heat exchanger, stabilizer tower bottom re-boiler, gas field water heat exchanger, acid water stripping tower top condenser, acid water stripping tower bottom re-boiler, gas field water cooler, flash gas compressor, three-phase separator acid water collection tank, condensate low tank amine purification unit, amine purification system.

6.Air-nitrogen station

Micro-oil worm air compressor, buffer tank, heatless regenerative adsorption dryer, pressure swing adsorption nitrogen plant skid, storage tank, purified air storage tank, nitrogen storage tank.

7.Fuel gas system

Fuel gas distribution tank, purified gas storage tank

8.Blow down flare system

High pressure blown down flare, low pressure blow down flare, high pressure blow down separator, low pressure blow down separator, sulfur-bearing waste water pressurizing tank

9.Condensate storage tank area

Inner floating roof condensate tank